FAQ

The two dehumidification methods with Physical adsorption and semiconductor microchip are adopted by EDRY. It is available to select the different components to assemble it depending on the request for anti-humidity. All of our products are made in Taiwan. We have experience in production and marketing since 1987.

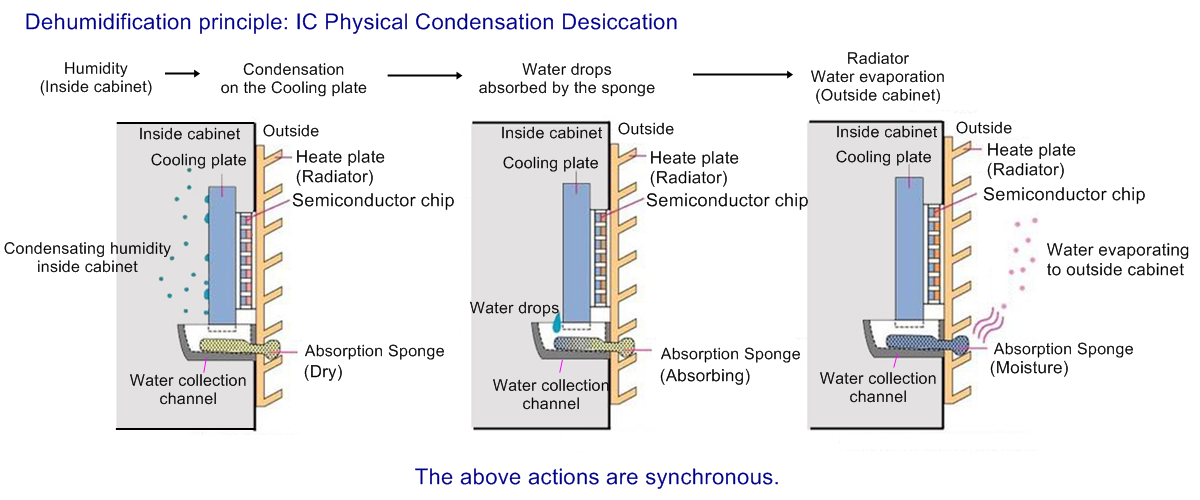

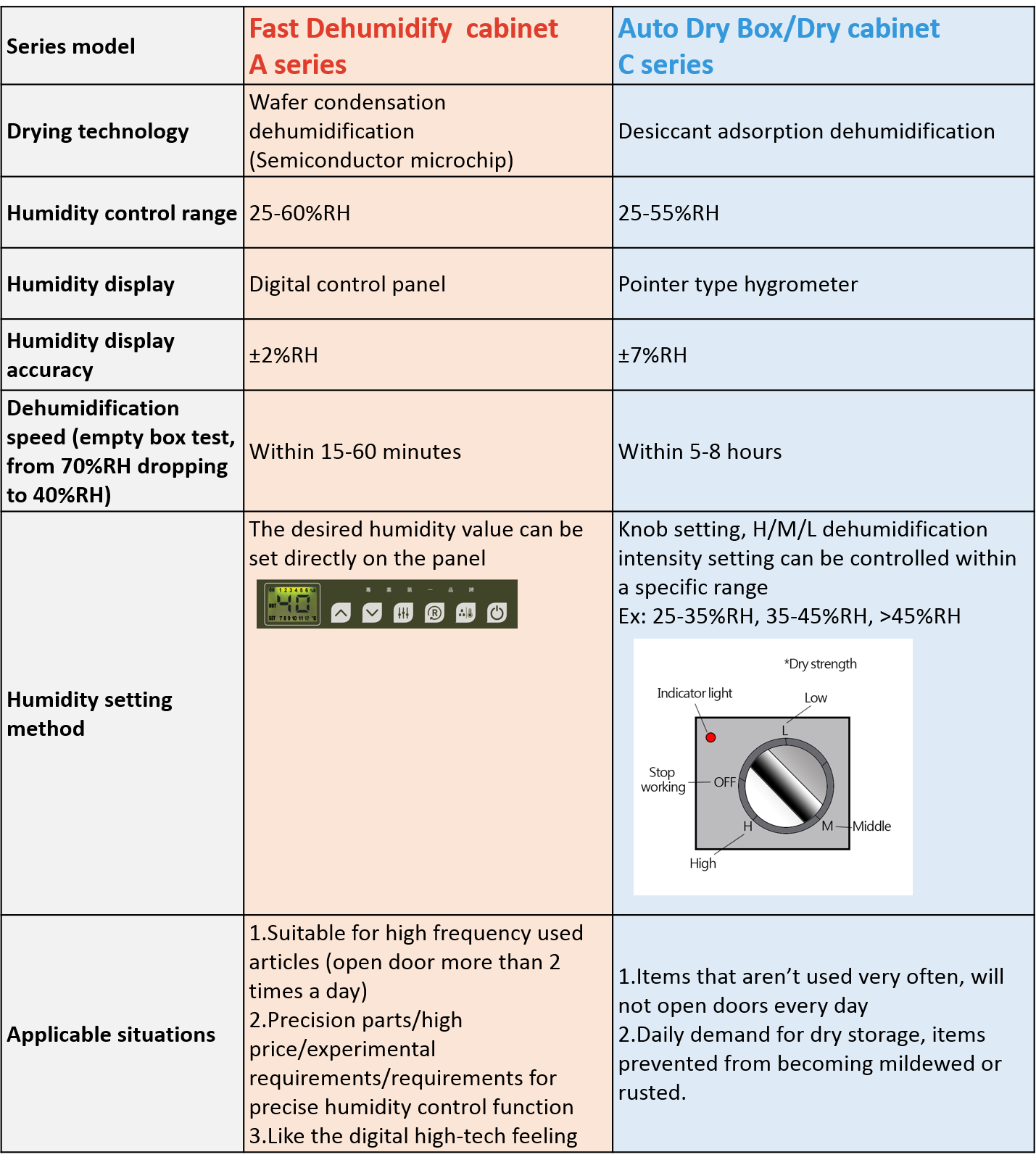

Semiconductor microchip (Condensation dehumidification)

Our semiconductor chip technology had through the patent certification.

The principle is like you take a cola out from refrigerator, the surface of can will condensate water, it use the temperature difference for dehumidification. The IC chip will cold less than 0 degrees, when the humidity exceeds the set value the fan in the dehumidifier will turn and start dehumidifying. And then the machine will stop operate when the humidity equals to set value. So the humidity can be stably maintained at plus and minus 2% of the set value. The dehumidifier performance is also stronger, the humidity can down from 70% to 40% within 30-60mins.

We made the breakthrough from traditional anti-humidity technology to create successfully the stable humidity environment, which is the safest and the most stable technology applied to anti-humidity.

However, the lowest humidity is 25%RH.

The two dehumidification methods with Physical adsorption and semiconductor microchip are adopted by EDRY. It is available to select the different components to assemble it depending on the request for anti-humidity. All of our products are made in Taiwan. We have experience in production and marketing since 1987.

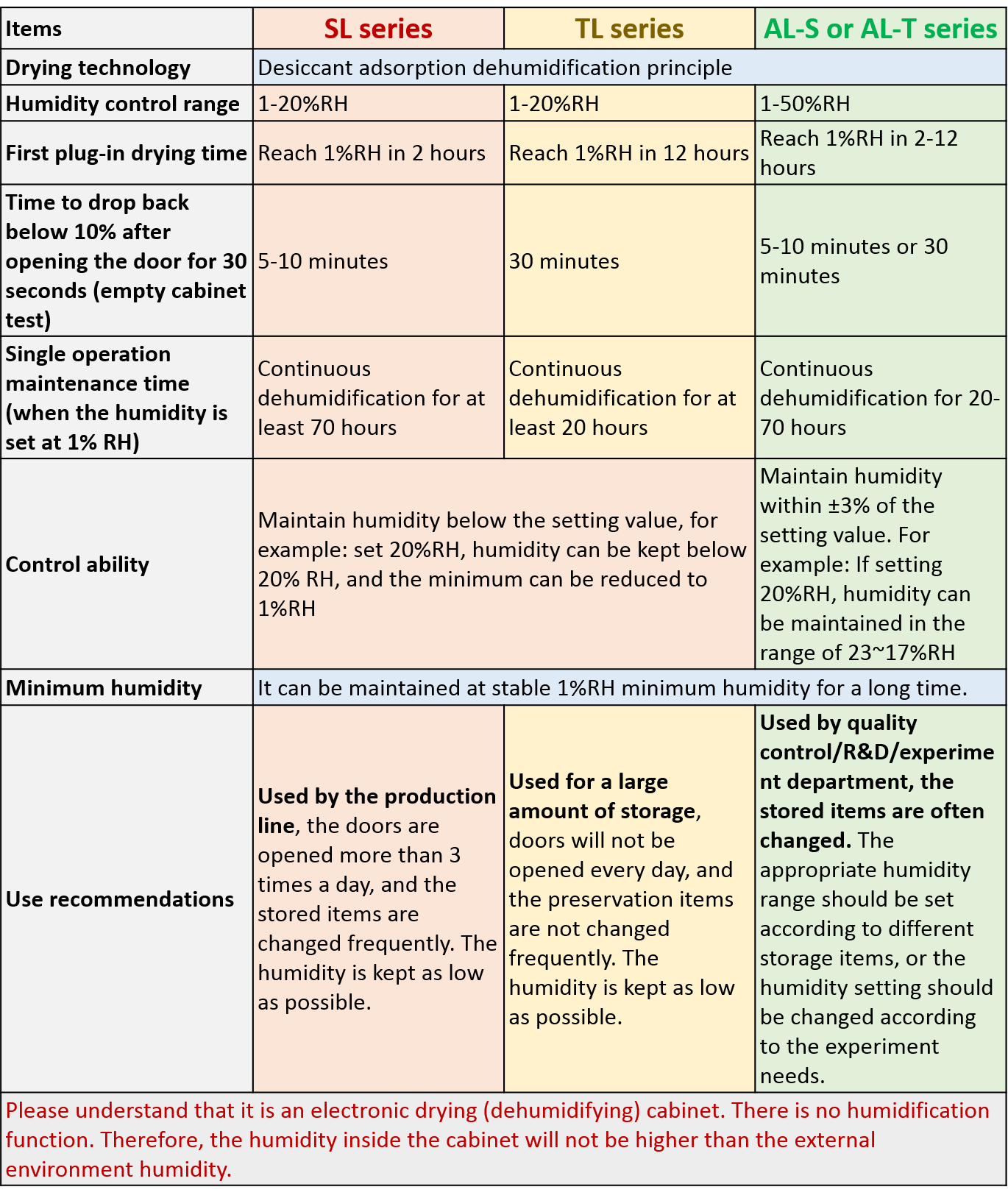

Physical adsorption Desiccant dehumidification technology

It use desiccant dehumidification technology, most of brand only have this kind of system in dry cabinet. it is suitable for camera electronic machine, food, drug or something else. In the dehumidifier we use recycled desiccant to absorb the humidity, when the desiccant full of humidity the machine will heat to release the humidity, as the desiccant back to dry state for dehumidifying again.

The dehumidification time will be longer, it needs 5 hours to make the humidity down from 70% to 40%RH. And the humidity control accuracy is ±7%RH.

It is suitable for common usage.

Desiccant

.jpg)

.jpg)

There are two working stage

- Absorption Stage:

The valves are opened inwards and closed outwards in order to absorb moisture inside the Dry cabinet to the desiccants in the Dry Unit. - Exhaustion Stage:

The valves are opened outwards and closed inwards in order to exhaust moisture out of the Dry cabinet from saturated desiccants in the Dry Unit by heating dessicants.

Both the stages will cycle automatically. The whole process is controlled by Shape Memory Alloy & an I.C. Timer.

For our ultra low humidity series is also use desiccant dehumidification technology.

However, the inside structure it different with common hygrometer type so that it can dehumidify to 1%RH, as much as possible to remove all humidity.

EDRY provides highly competitive stable prices and high-quality Taiwan-made adherence to quality standards! Compared with other brands, the ultra-low humidity and strong dehumidification technology of EDRY can maintain a humidity of 1%RH for a long time, and the humidity can be reduced to below 10%RH within 5 minutes after opening and closing the door. It can be reduced to 1%RH within 10 minutes, and the humidity control range can be freely selected between 1%RH and 50%RH. This high-efficiency dehumidification function can completely replace high-cost drying equipment such as nitrogen cabinets and high-temperature baking ovens. It is definitely the best choice for customers!

Do you know that ultra-low humidity has a large market!?

Applicable industries:

Industrial manufacturing, semiconductor technology, aerospace technology, military weapons manufacturing, solar energy, school education, national laboratories, and so on.

Applicable storage items:

Precious metals, precision instruments, semi-finished products, chips, IC boards, PCB integrated circuit boards, dies, wafers, military weapons, electronic components, optical supplies, LED parts, 3D printer filaments, pharmaceutical raw materials, laboratory drugs, etc. are all potential development markets!

Replaces drying equipment such as nitrogen cabinets and baking ovens, etc. Electronic humidity control cabinets (Auto Dry Boxes) feature no consumables, low power consumption, no need for regular maintenance, and are long-lasting and durable!

Utilize desiccant adsorption dehumidification principle

The dehumidification movement core is equipped with a desiccant box, and the heater is arranged in the box to repeat the cycle operation. The operation of the movement core is divided into two stages, dehumidifying (absorbing moisture in the cabinet) and draining (evasively dispersing the absorbed water from the cabinet)

Dehumidification phase: Close the outside door valve of the cabinet and open the inner door valve at the same time so that the desiccant can absorb moisture from the cabinet.

Draining phase: Close the inner door valve and open the outer door valve. Heat the dry material for about 40-50 minutes to evaporate the water

Combined with patented design optimization on multiple technical structures, it extends the durability of parts to achieve ultra-low humidity (1%RH) with almost no moisture and extremely fast dehumidification (recovering 10%RH or less in 5 minutes).

The following warranty methods are only applicable to sales markets outside of Taiwan

*Warranty: The dehumidification movement core and hygrometer provide at least one year warranty.

*Both the dehumidification movement core and the hygrometer are designed in DIY and can be disassembled and installed by the user.

*During the warranty period: After confirming the abnormal operation of the machine with EDRY, please send the movement core and hygrometer back to the original factory in Taiwan to check the cause of the fault, such as the judgment for natural damage. After receiving the faulty parts, EDRY will send a replacement product movement core or hygrometer within a week, no charge at all.

If the damage is judged to be due to an artificial factor, maintenance charges will be assessed.

Parts shipping cost:

The cost of returning abnormal parts to the original factory shall be paid by the buyer;

Replacement parts sent to the final customer, the shipping charges will be paid by EDRY.

*After the expiry of the warranty: 1.We recommend that the parts be sent back to Taiwan for maintenance, and a repair fee for the parts will be charged. 2. After consultation, if it is recommended to buy a new movement core and hygrometer to replace directly, no need to return those parts. All out of warranty shipping costs are paid by the buyer.

*Average product life

Desiccant adsorption dehumidification: At least 10 years or more

Semiconductor wafer condensation and dehumidification: at least 20 years or more

Ultra-low humidity drying application <20%RH

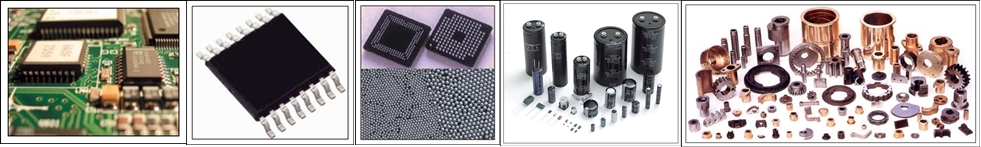

Most of our customers purchase this model to store their electronic components or some chemical drug, medicine, materials.

For example, Integrated circuits (QFP, CSP, PGA, BGA, SOP, TQFP), PCB, silicon wafers, diodes, transistors, rectifiers, LED, solar panels…etc.

The humidity must be controlled below 10%RH even to 1%RH, as far as possible to remove all the moisture inside the cabinet

General humidity Dry cabinet application 25-60%RH

Ultra low dry storage cabinet application for the electronic and the manufacturing industries

(Semi-conductors, electronic components, consumer electronics, communication technology, information technology, photonics, industrial instruments, etc....)

.jpg)

Do you know”that trace moisture”has great impact on the quality of electronic components and electronic circuits? Resultsfrom surveys suggest that more than 25% of industrial defects, including defects from the industries of photonics, semi-conductors, electronics, biotechnology, food, drugs, and optics, are caused by a lack of low humidity storage. At present, manufacturing defects encountered by the electronic industry, can happen at the following stages

1. Damage due to micro-cracks in the heating process during SND/IC sealing and packaging;

2. The water hazard during SMT reflow soldering because of returned water temperature in the baking process;

3. IC oxidation caused by damped packaging materials;

4. Damp and moldy LCD boards;

5. Delamination of PCB multilayer printing and circuit boards caused by temperature difference and humidity;

6. Weld leg oxidation due to humidity caused poor solderability.…ect‚

Therefore improving the condition of trace moisture for manufacturing, quality control, R&D, and warehousing is indispensible.

EDRY uses J-STD-033B protocol as the foundation for organizing ways to resolve or reduce damp problems caused by trace moisture in the industry and explains conditions in which floor life be reset or paused.

MSL If SMD components of MSL2 or above are not stored in dry packs (must be within the floor life), these components have to be re-dehydrated. If the required components are frequently dried repeatedly or for a long time in the oven, reliability of the components still can drop. In this case, room temperature dehydration is extremely important. For majority components, storing them below 10% RH fulfills the J-STD-033B protocol, and in this case, one no longer need to worry any possible negative effects caused by baking at high temperature and for long time or repetitive baking.

-1(1).jpg)

Table 4-3 Resetting or Pausing the ‘‘Floor Life’’ Clock at User Site

| MSL Level | Exposure Time @ Temp/Humidity | Floor Life | Desiccator Time @ Relative Humidity | Bake | Reset Shelf Life |

| 2, 2a, 3, 4, 5, 5a | Anytime ≦40°C/85% RH |

reset | NA | Table 4.1 | Dry Pack |

| 2, 2a, 3, 4, 5, 5a | ≦ floor life ≦30°C/60% RH |

reset | NA | Table 4.1 | Dry Pack |

| 2a, 3, 4 | >12 hrs ≦30°C/60% RH |

reset | NA | Table 4.1 | Dry Pack |

| 2, 2a, 3, 4 | ≦12 hrs ≦30°C/60% RH |

reset | 5X exposure time ≦10% RH |

NA | NA |

| 5, 5a | >8 hrs ≦30°C/60% RH |

reset | NA | Table 4.1 | Dry Pack |

| 5, 5a | ≦8 hrs ≦30°C/60% RH |

reset | 10X exposure time ≦5% RH |

NA | NA |

| 2, 2a, 3 | Cumulative time ≧floor life ≦30°C/60% RH |

pause | Anytime ≦10% RH |

NA | NA |

Moisture sensitivity levels (MSL) is listed in ascending order, and smaller numbers suggest better moisture proof capacity, while bigger numbers suggest that a shorter exposure to environmental humidity is required.

|

|

|

|

|

|

Table 5-1 lists floor life of components with different moisture sensitivity level at 30°C/60%RH (If a component is exposed to air for more than one hours, follow the operation listed in Table 7-1)

Table 5-1 Moisture Classification Level and Floor Life

| Level |

Floor Life (out of bag) at factory |

| 1 |

Unlimited at 30°C/85% RH. No control is required as long as 30°C/85% |

| 2 |

1year |

| 2a |

4 weeks |

| 3 |

168 hours |

| 4 |

72 hours |

| 5 |

48 hours |

| 5a |

24 hours |

| 6 |

Mandatory bake before use. After bake, must be reflowed within the time limit specified on the label. |

Table 7-1 Shelf life (in days) for different moisture sensitivity level at different moisture preservation environment

(1).jpg)

It can be found from the above table that as long as humidity is maintained under 10%RH and 5% RH, shelf life of components can be infinitely extended. It is especially true when the components are stored in an environment with humidity below 5% RH.

It can be found from the above data that during the manufacturing process of electronics, it is important to effectively control trace moisture to elevate the yield rate. Trace moisture is an important issue for components, parts, solder balls, solder paste, etc. In fact, to elevate products’ yield rate effectively, the component stage is much more important than the semi-product or final product stage.

Dry box, Dry cabinet , Desiccator cabinet, Ultra dry storage<5%RH application

Integrated circuits (QFP, CSP, PGA, BGA, SOP, TQFP), PCB, diodes, transistors, rectifiers, LED, solar panels, SMD, resistance device, capacitance device, conductive materials, printed circuit boards, welding materials, solder balls, solder paste, dehumidifiers, optical fibers, chemicals, quartz crystals, quartz oscillators, mica, ceramics, molds, machine parts, samples, etc.